Wire rope lubricators, wire cleaners and other sophisticated tools are essential in the complex field of maintenance for cables. Precision and longevity is paramount. These cutting-edge devices are essential to ensure that cables function smoothly and last longer across an array of industries. Cleaners for ropes and ropes are crucial for maintenance of cables. In this piece, we explore their functions, advantages and the positive effects they have on overall efficiency.

Understanding Wire Rope Lubricators:

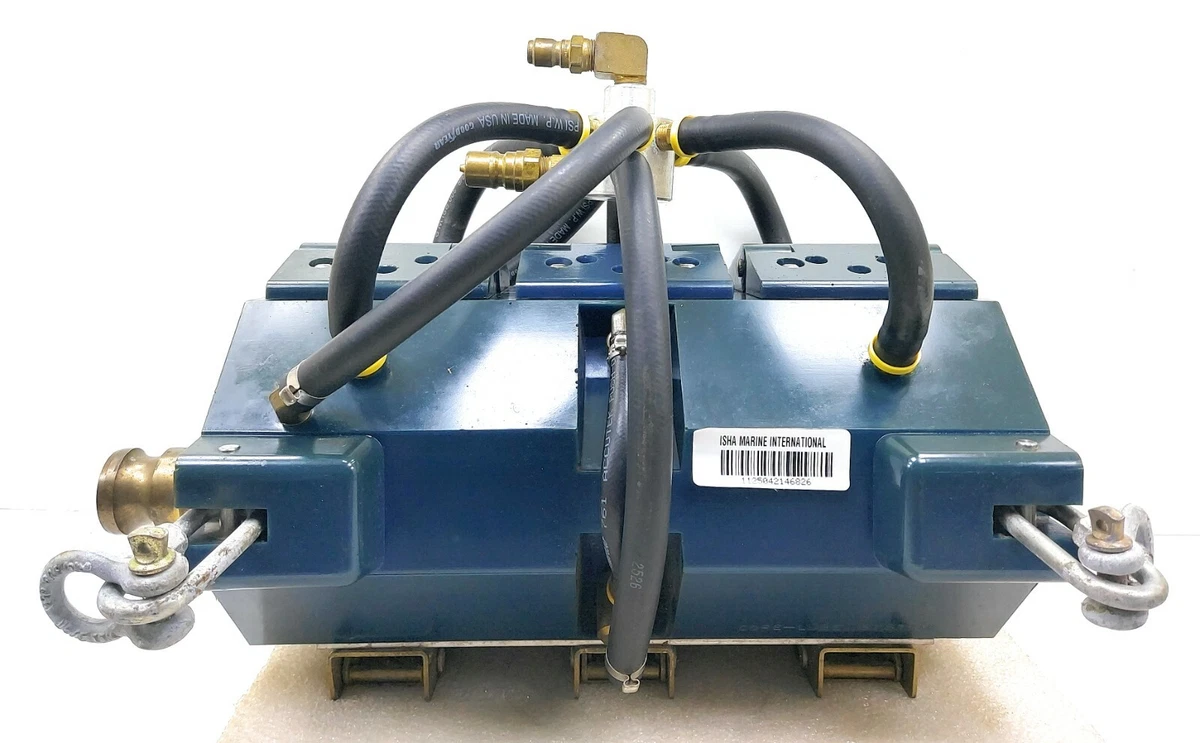

Wire Rope Lubricators are specialized machines designed to ensure that wire ropes are lubricated in an organized method. This process is vital in preventing rust, decreasing friction and increasing the overall durability. The lubricator is responsible for ensuring that the lubricants are evenly distributed over the length of wire ropes guarding them against wear and tear.

What is the role of wire cleaners in cable maintenance?

Cable cleaners and wire cleaners are both necessary to ensure clean cables. These cleaners are created to get rid of contaminants, fluids and dirt that be accumulated on cables throughout different tasks. Wire cleaners are crucial for harsh environments, in which cables can be subjected to extreme conditions. They ensure optimal performance and protect against damage to the cable.

Optimizing Cable Lifespan:

Combining wire cleaners with the lubrication of wire rope can prolong the cable’s lifespan. Wire cleaners as well as wire rope lubricators are used to systematically apply lubrication, and then remove any dirt. They also shield cables from friction, corrosion as well as other external forces. The cable’s integrity is preserved and this results in greater efficiency of operation and lower maintenance costs.

The efficiency of the application

Wire rope lubricators have been created to be simple to use and efficient in application. The lubricators can be used with a wide range different sizes and types of wire ropes. This allows for versatility in the cable maintenance. The automated and systematic application of lubrication ensures consistency which eliminates the chance of inconsistency that manual processes may pose.

Adaptability in Challenging Environmentals:

In sectors where cables are exposed to harsh environments, like those in drilling, construction or maritime activities The adaptability of wire rope lubricators or wire cleaners is crucial. These devices have been designed to be able to withstand harsh conditions. They are therefore reliable devices for maintaining cables.

Solutions for maintenance that are cost effective:

An approach that is proactive to cable care using grease and cleaners for wire rope, is a more cost-effective option in the long term. These modern tools are an affordable investment when as compared to the expense of cable replacements, repairs and downtime which could be caused by neglecting maintenance. Know more at Wire Cleaning

Conclusion:

Lubricators and cleaners for wire cables are the guardians who ensure cable integrity and accuracy across a variety of industries. The systematic application of lubrication and the removal of dirt contributes to the longevity of cables, eventually making maintenance less costly and improving operational efficiency. Cables are still utilized in the most critical sectors, therefore using cable maintenance tools that will help ensure reliability and efficiency is a must.